PP green environmental protection materialWhat's the Corflute Plastic Sheet?

Corflute Plastic Sheet is a twin wall profile extrusion, connected by a series of vertical ribs, also called Coreflute, Corflute, Correx Sheet,Corex Sheet, PP coroplast Sheet, Corrugated Plastic Sheet etc. The corflute plastic sheet can be widely used in packaging, advertising, construction, agriculture, hardware, layer pad industry and others.

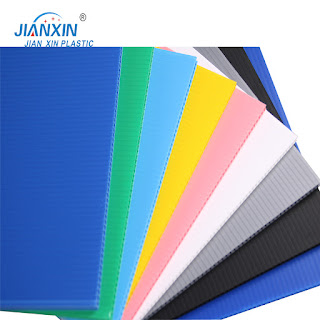

The corflute plastic sheet is diversity in color, thickness, density,size, types. The thickness range 1.8MM-12MM, density 180gsm-3000gsm, maximum width 2300MM and length according to customer requirements. It can be made into trellis shape, S shape, W shape, X shape and so on.

What's the working process of the Corflute Plastic Sheet?

The Corflute Plastic Sheet is made from HDPP(100% new high density polypropylene raw materials) material. The produce process is : HDPP material(raw material +desiccant+ color masterbatch)→blender→extruding machine(Raw material melt pluralization)→mould(Forming extrusion)→Finalize the design→The first traction→Oven→cooler→The second traction→Shears→Stacked platform.

The features of the Corflute Plastic Sheet:

- Non-toxic, Tasteless

- PP Green Environmental Protection Material

- Moisture resistance, corrosion resistance

- Less consumables, Low cost, Light weight

- Surface can be printed or paste the composite film

- Can produce different colors according to demand

- Accept UV Printing, Silk Screen Printing

- Anti-static,fire-retardant

- Suitable temperature -40℃-200℃

Want to know more details? Please click on:

Contact Us:

Factory: Dongguan Jian Xin Plastic Products Co., Ltd.

Website: www.corrugatedplasticsheet.net

ADD: NO.94 QingFeng East Road ShiJie Town, DongGuan City, GuangDong Province, China. Postcode 523296

Tel: +86-769-86308368

WhatsApp: 8613631764169/8613794991619

E-mail: jianxin@jx-plastic.com